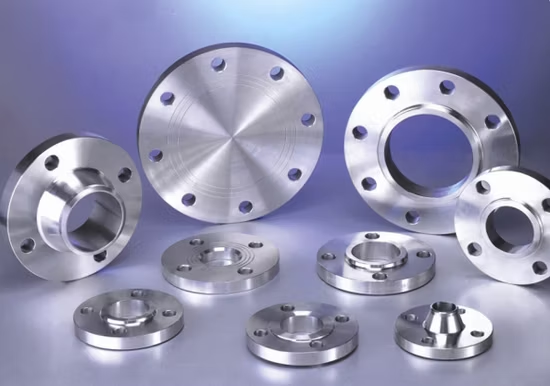

Gr 1/2/5/7/9 Titanium Alloy Steel Pn 16 Welding Neck RF Flange

Surface:Black painting,varnish paint, anti rust oil, hot galvanized, cold galvanized, 3PE,etc. Application:Low and middl;

Basic Info.

| Model NO. | EL-TF |

| Manufacturing Way | Forging |

| Alloy or Not | Non Alloy |

| Standard or Not | Standard |

| Price Term | Fob,CIF,CNF |

| Payment | L/C,T/T |

| Secindary or Not | Non Secondary |

| Flange Type | Pl,Wn,So,Th,Sw,Lj,Bl,etc. |

| Face | RF / FF / Mfm/ Tg/ Rtj... |

| Delivery Detail | 15-30 Days After Down Payment |

| Certificate | ISO,TUV,Ad |

| Transport Package | in Wooden Case or Pallet |

| Specification | 1/2"-72" |

| Trademark | Kingmetal |

| Origin | China |

| HS Code | 730791 |

| Production Capacity | 5000000 PCS Per Month |

Product Description

| Item name | Titanium flange |

| Standard | ASME/ANSI B16.5,DIN2630~2633,BS etc |

| Material | Gr1,Gr2,Gr5,Gr7,Gr9,Gr12,etc. |

| Size | 1/2''~80''(DN10~600) |

Pressure rating | 0.6~32Mp |

| (DIN) PN6,PN10,PN16,PN25 though PN250 | |

| (ASNI) CL150,CL300,CL600,CL900,CL1500 | |

| Working temperature | -60°C~250°C |

| Flange surface | FF,RF,TG,RJ etc |

| Quality control | Ultrasonic Testing & Material Test Report |

| Packaging | Plywood case line with foam or as per clients request |

Surface:Black painting,varnish paint, anti rust oil, hot galvanized, cold galvanized, 3PE,etc.

Application:Low and middle pressure fluid pipeline,boiler, petroleum and natural gas industry,drilling,chemical industry, electric industry,shipbuilding,fertilizer equipment and pipeline, structure,petrochemical,pharmaceutical industry

2. Chemical requirements

N | C | H | Fe | O | Al | V | Pa | Mo | Ni | Ti | |

Gr 1 | 0.03 | 0.08 | 0.015 | 0.20 | 0.18 | / | / | / | / | / | bal |

Gr 2 | 0.03 | 0.08 | 0.015 | 0.30 | 0.25 | / | / | / | / | / | bal |

Gr 5 | 0.05 | 0.08 | 0.015 | 0.40 | 0.20 | 5.5~6.75 | 3.5~4.5 | / | / | / | bal |

Gr 7 | 0.03 | 0.08 | 0.015 | 0.30 | 0.25 | / | / | 0.12~0.25 | / | / | bal |

Gr 9 | 0.03 | 0.08 | 0.015 | 0.25 | 0.15 | 2.5~3.5 | 2.0~3.0 | / | / | / | bal |

Gr12 | 0.03 | 0.08 | 0.015 | 0.30 | 0.25 | / | / | / | 0.2~0.4 | 0.6~0.9 | bal |

grade | Tensile strength(min) | Yeild strength(min) | Elongation(%) | ||

ksi | MPa | ksi | MPa | ||

1 | 35 | 240 | 20 | 138 | 24 |

2 | 50 | 345 | 40 | 275 | 20 |

5 | 130 | 895 | 120 | 828 | 10 |

7 | 50 | 345 | 40 | 275 | 20 |

9 | 90 | 620 | 70 | 438 | 15 |

12 | 70 | 438 | 50 | 345 | 18 |

You may also like

Send inquiry

Send now