Factory Price Titanium Investment Casting Customized

Basic Info.

| Surface Roughness | Ra6.3 |

| Machining Tolerance | +/-0.02mm |

| Standard | ASME |

| Certification | CE, RoHS, ISO 9001:2000, ISO 9001:2008 |

| Lead Time | 30 Days |

| Inspection | 100% Visual Inspection |

| Certificates | ISO9001:2015 |

| MOQ | 100 PCS |

| Package | Cartons+Wooden Case/Pallet |

| Surface | Sand Blasting, Polishing, Elctropolishing |

| Casting Tolerance | CT4-CT6 |

| Product Name | OEM Casting Service |

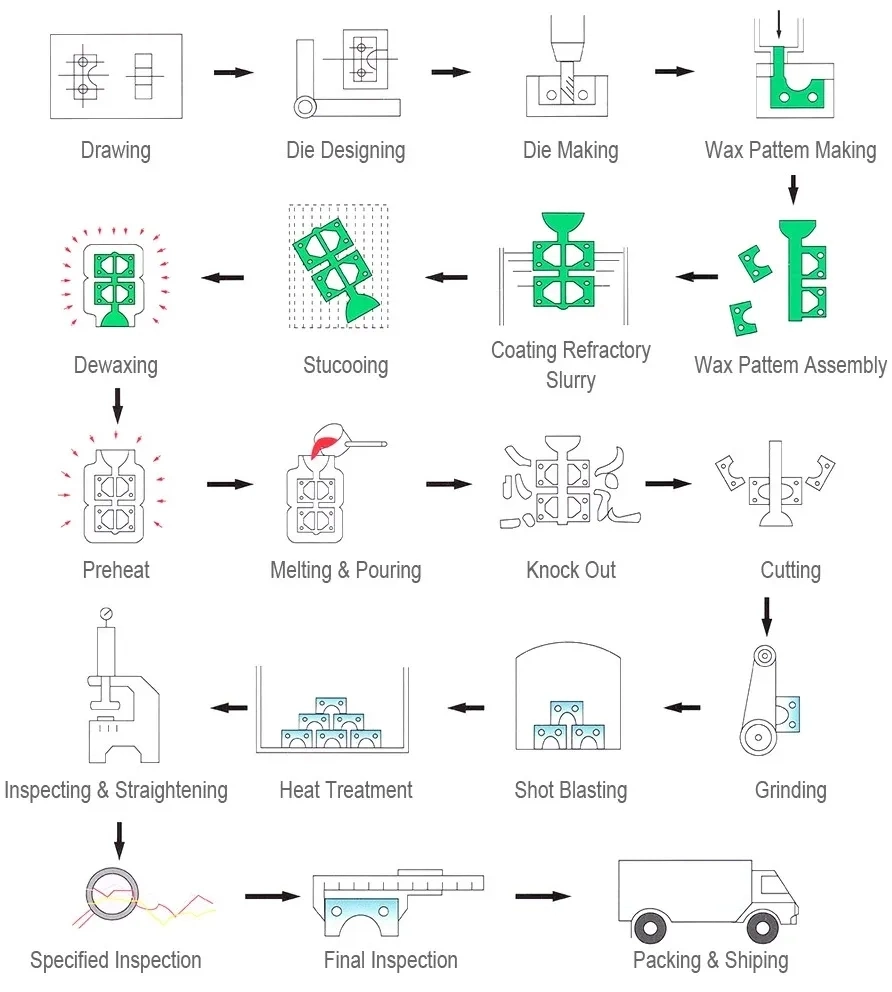

| Technology | Investment Casting, Die Casting, Gravity Casting |

| Transport Package | Bubble Bag+Cardboad Carton+Pallet |

| Specification | OEM |

| Trademark | Hongsheng |

| Origin | China |

| HS Code | 8302410000 |

| Production Capacity | 100tons/Month |

Product Description

OEM aluminum/stainless steel/alloy steel/brass sand die casting precision investment casting service

Product Parameters

| R&D | Softward: Solidworks, CAD, Procast, UGDevelopment cycle of samples: 25-35 days |

| Materials | Stainless steel: 304/304L, 316/316L, 410/416 etcDuplex stainless steel: 2250, 2507Carbon steel, Alloy steel, Aluminum,zinc alloy, brass/bronze... |

| Technical Parameter | Part weight: 2g to 30kgsMax dimension : 600mm for diameter or lengthMin wall thickness : 1.5mmCasting roughness: Ra3.2-6.4 Machining roughness: Ra1.6Tolerance of casting: CT6Inner core: ceramic core, urea core, water soluble wax core. |

| Heat treatment | Normalzing, Tempering, Quenching, Annealing, Quenching & Tempering, Caburization, Solution treatment. |

| Surface treatment | Polishing, bead blasting, zinc plating, hot dip galvanized, nickel plating, passivation, Electro-polising, mirror polishing, Brush polishing, PE coating, Powder coating, etc |

| Inspection | Cleanliness inspection, X-Ray radiographic inspection, MIM inspection |

| Production capacity | More than 120 tons per month |

| Quality Certificates | ISO9001ISO14001 |

Detailed Photos

Our Service

Company Profile

Certifications

- Hongsheng holds the ISO 9001 :2008 and ISO 1 4001 :2004 certifications and therefore complies with all the essential quality control procedures and environmental respect rules which guarantee the reliability of all our manufactured products, both during the direct processes and in the auxiliary workshops.

Packaging & Shipping

FAQ

Q1: What is our payment term?

A:T/T, Paypal. Q2: How can we quote for you?

A: Please email us enquiry with all technical drawings you have, such as material grade, tolerance, mechanicalproperties, heat treatment, requirements, etc. Our specialized engineers will check and quote for you within 24 hours. Q3: Which product are often processed by your company ?

A: Auto parts,machinery part, marine part, Kitchen parts, Agricultural parts.Q4: Which material are often used ? A: Stainless steel. alloy steel, carbon steel, aluminum, copper.Q5: Which finish you can provide ?

A:Sand blasting, Tumbling, Polishinh, Electro-polishing, Mirror Polishing, Powder coating, Electrophoresis, ETC.Q6: What is the MOQ ? A: Based on the product, normal 100 pcs.Q7: Can we make the samples? A: Is Available, 15-20days for sampling.Q8: How about for the lead time?

A: Normally about 35 days for mass production, pls inform us if it is urgent order.